| Instrumentation Cables | ||||||||||||||

![]() EN 50288-7 Instrumentation Cables

EN 50288-7 Instrumentation Cables

PE Insulated, LSZH Sheathed, Overall Screened & Armoured Instrumentation Cables (Multitriple)

RE-2Y(St)HSWAH 70°C / 300 V

STANDARDS

Basic design to EN50288-7

APPLICATION:

These cables are used for transmission of analoge and digital signals in instrument and control systems at chemistry and petr°Chemistry

industry plants, power plants, natural gas and petroluem plants, etc...

These cables are used in the environments which have no corrosive gases are emitted in the event of fire. In case of fire,

these cables inhibit the propagation of the flames whereby the development of smoke is extremely low. Instrumentation

cables are not allowed for direct connection to a low impedance sources, e.g. public mains electricity supply. With blue

sheath it is suitable for intrinsically safe systems. These cables are not recommended for direct burial. They are for indoor and outdoor installation, in dry and wet l°Cations; on racks, trays, in conduits.

FIRE PERFORMANCE

| Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

| Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

| Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

| No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

| Minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

| No Toxic gases | NES 02-713; NF C 20-454 |

| Sunlight Resistance | UL 1581 section 1200 |

| Oil Resistance | ICEA S-73-532** |

Note: Asterisk * denotes superseded standard, **Test temperature +60°C, duration 4h. Retention: min 60% of tensite strength/min.60% of elongation.

VOLTAGE RATING

300V

CABLE CONSTRUCTION

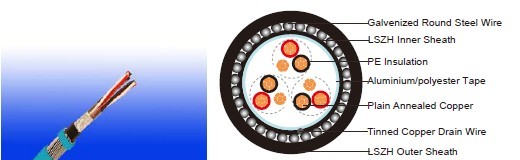

Conductor: Annealed copper solid or plain copper stranded to IEC 60228 Class 2.

Insulation: PE compound, EN 50290. 2-23.

Pair:Two conductors twisted to form a pair

Lay-up: Pairs laid up in layers of optimum pitch

Separator: Polyester tape

Overall Screen: Aluminium/polyester tape with tinned copper drain wire, 0.5mm2

Inner sheath: HFFR compound, EN 50290-2-27

Armour: Galvenized round steel wire, EN 10257-1

Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH compound type

SW2-SW4 as per BS 7655-2.6 can be offered.). UV resistance, hydrocarbon resistance, oil resistance, anti rodent and

anti termite properties can be offered as option.

COLOUR CODE

Insulation: Black / White / Red, continuously numbered on white core(1, 2..)for multitriples.

Outer Sheath: Black or blue for intrinsically safe systems

Physical AND THERMAL PROPERTIES

Temperature Range During Operation (Fixed State): -30°C – +70°C

Temperature Range During Installation (Mobile State): -5°C – +50°C

Minimum Bending Radius: 10 X Overall Diameter

CONSTRUCTION PARAMETERS

Caledonian Cable Code |

RE-2Y(St)HSWAH |

|||||||

| No. of Triples x3xCross Section | Nominal Insulation Thick-ness | Nominal Inner Sheath Thick -ness | Nominal Overall Diameter Over Inner Sheath | Nominal Armour Wire Diameter | Nominal Outer Sheath Thick-ness | Nominal Overall Diameter | Approx. Weight | |

| No.x3xmm2 | mm | mm | mm | mm | mm | mm | kg/km | |

| 0.5mm2, Multitriple | ||||||||

| RE-2Y(St)HSWAH 2T0.5 | 2x3x0.5 | 0.35 | 0.9 | 8.4 | 0.9 | 1.4 | 13.0 | 326 |

| RE-2Y(St)HSWAH 4T0.5 | 4x3x0.5 | 0.35 | 1.0 | 9.8 | 0.9 | 1.4 | 14.4 | 386 |

| RE-2Y(St)HSWAH 5T0.5 | 5x3x0.5 | 0.35 | 1.0 | 10.8 | 0.9 | 1.4 | 15.4 | 454 |

| RE-2Y(St)HSWAH 6T0.5 | 6x3x0.5 | 0.35 | 1.0 | 12.1 | 0.9 | 1.4 | 16.7 | 513 |

| RE-2Y(St)HSWAH 8T0.5 | 8x3x0.5 | 0.35 | 1.1 | 13.1 | 0.9 | 1.5 | 17.9 | 571 |

| RE-2Y(St)HSWAH 10T0.5 | 10x3x0.5 | 0.35 | 1.1 | 14.7 | 0.9 | 1.5 | 19.5 | 677 |

| RE-2Y(St)HSWAH 12T0.5 | 12x3x0.5 | 0.35 | 1.1 | 15.2 | 0.9 | 1.5 | 20.0 | 845 |

| RE-2Y(St)HSWAH 16T0.5 | 16x3x0.5 | 0.35 | 1.2 | 17.4 | 0.9 | 1.6 | 22.4 | 1031 |

| RE-2Y(St)HSWAH 20T0.5 | 20x3x0.5 | 0.35 | 1.2 | 19.1 | 1.25 | 1.6 | 24.8 | 1179 |

| RE-2Y(St)HSWAH 24T0.5 | 24x3x0.5 | 0.35 | 1.3 | 20.9 | 1.25 | 1.7 | 26.8 | 1330 |

| 0.75mm2, Multitriple | ||||||||

| RE-2Y(St)HSWAH 2T0.75 | 2x3x0.75 | 0.38 | 1.0 | 10.6 | 0.9 | 1.4 | 13.9 | 370 |

| RE-2Y(St)HSWAH 4T0.75 | 4x3x0.75 | 0.38 | 1.1 | 12.4 | 0.9 | 1.4 | 15.5 | 462 |

| RE-2Y(St)HSWAH 5T0.75 | 5x3x0.75 | 0.38 | 1.1 | 13.7 | 0.9 | 1.4 | 16.6 | 526 |

| RE-2Y(St)HSWAH 6T0.75 | 6x3x0.75 | 0.38 | 1.1 | 15.4 | 0.9 | 1.5 | 18.5 | 615 |

| RE-2Y(St)HSWAH 8T0.75 | 8x3x0.75 | 0.38 | 1.2 | 16.7 | 0.9 | 1.5 | 19.5 | 698 |

| RE-2Y(St)HSWAH 10T0.75 | 10x3x0.75 | 0.38 | 1.3 | 19.0 | 0.9 | 1.5 | 21.5 | 947 |

| RE-2Y(St)HSWAH 12T0.75 | 12x3x0.75 | 0.38 | 1.3 | 19.7 | 0.9 | 1.7 | 22.3 | 1029 |

| RE-2Y(St)HSWAH 16T0.75 | 16x3x0.75 | 0.38 | 1.4 | 22.5 | 1.25 | 1.6 | 25.4 | 1240 |

| RE-2Y(St)HSWAH 20T0.75 | 20x3x0.75 | 0.38 | 1.5 | 24.9 | 1.25 | 1.7 | 27.6 | 1446 |

| RE-2Y(St)HSWAH 24T0.75 | 24x3x0.75 | 0.38 | 1.6 | 27.2 | 1.25 | 1.7 | 29.6 | 1632 |

| 1.0mm2, Multitriple | ||||||||

| RE-2Y(St)HSWAH 2T1.0 | 2x3x1 | 0.4 | 1.0 | 11.5 | 0.9 | 1.4 | 15.0 | 412 |

| RE-2Y(St)HSWAH 4T1.0 | 4x3x1 | 0.4 | 1.1 | 13.4 | 0.9 | 1.4 | 16.5 | 529 |

| RE-2Y(St)HSWAH 5T1.0 | 5x3x1 | 0.4 | 1.1 | 14.8 | 0.9 | 1.5 | 18.0 | 620 |

| RE-2Y(St)HSWAH 6T1.0 | 6x3x1 | 0.4 | 1.2 | 16.9 | 0.9 | 1.5 | 19.8 | 830 |

| RE-2Y(St)HSWAH 8T1.0 | 8x3x1 | 0.4 | 1.2 | 18.1 | 0.9 | 1.5 | 20.9 | 946 |

| RE-2Y(St)HSWAH 10T1.0 | 10x3x1 | 0.4 | 1.3 | 20.7 | 0.9 | 1.6 | 24.1 | 1105 |

| RE-2Y(St)HSWAH 12T1.0 | 12x3x1 | 0.4 | 1.3 | 21.4 | 1.25 | 1.6 | 24.7 | 1215 |

| RE-2Y(St)HSWAH 16T1.0 | 16x3x1 | 0.4 | 1.4 | 24.4 | 1.25 | 1.7 | 27.6 | 1482 |

| RE-2Y(St)HSWAH 20T1.0 | 20x3x1 | 0.4 | 1.5 | 27.1 | 1.25 | 1.7 | 30.0 | 1740 |

| RE-2Y(St)HSWAH 24T1.0 | 24x3x1 | 0.4 | 1.6 | 29.6 | 1.25 | 1.8 | 32.2 | 2202 |

| 1.3mm2, Multitriple | ||||||||

| RE-2Y(St)HSWAH 2T1.3 | 2x3x1,3 | 0.45 | 1.1 | 12.8 | 0.9 | 1.4 | 16.1 | 463 |

| RE-2Y(St)HSWAH 4T1.3 | 4x3x1,3 | 0.45 | 1.1 | 14.7 | 0.9 | 1.5 | 18.2 | 621 |

| RE-2Y(St)HSWAH 5T1.3 | 5x3x1,3 | 0.45 | 1.2 | 16.5 | 0.9 | 1.5 | 19.6 | 721 |

| RE-2Y(St)HSWAH 6T1.3 | 6x3x1,3 | 0.45 | 1.3 | 18.8 | 0.9 | 1.5 | 21.7 | 979 |

| RE-2Y(St)HSWAH 8T1.3 | 8x3x1,3 | 0.45 | 1.3 | 20.1 | 0.9 | 1.6 | 23.8 | 1105 |

| RE-2Y(St)HSWAH 10T1.3 | 10x3x1,3 | 0.45 | 1.4 | 23.0 | 1.25 | 1.7 | 26.6 | 1322 |

| RE-2Y(St)HSWAH 12T1.3 | 12x3x1,3 | 0.45 | 1.5 | 24.0 | 1.25 | 1.7 | 27.3 | 1456 |

| RE-2Y(St)HSWAH 16T1.3 | 16x3x1,3 | 0.45 | 1.6 | 27.4 | 1.25 | 1.8 | 30.5 | 1788 |

| RE-2Y(St)HSWAH 20T1.3 | 20x3x1,3 | 0.45 | 1.7 | 30.4 | 1.25 | 1.8 | 33.2 | 2327 |

| RE-2Y(St)HSWAH 24T1.3 | 24x3x1,3 | 0.45 | 1.8 | 33.1 | 1.60 | 1.9 | 36.6 | 2637 |

1.5mm2, Multitriple |

||||||||

| RE-2Y(St)HSWAH 2T1.5 | 2x3x1,5 | 0.45 | 1.1 | 13.2 | 0.9 | 1.4 | 16.5 | 518 |

| RE-2Y(St)HSWAH 4T1.5 | 4x3x1,5 | 0.45 | 1.2 | 15.4 | 0.9 | 1.5 | 18.8 | 674 |

| RE-2Y(St)HSWAH 5T1.5 | 5x3x1,5 | 0.45 | 1.2 | 17.1 | 0.9 | 1.5 | 20.2 | 869 |

| RE-2Y(St)HSWAH 6T1.5 | 6x3x1,5 | 0.45 | 1.3 | 19.5 | 0.9 | 1.6 | 22.6 | 1049 |

| RE-2Y(St)HSWAH 8T1.5 | 8x3x1,5 | 0.45 | 1.4 | 21.1 | 1.25 | 1.6 | 24.8 | 1210 |

| RE-2Y(St)HSWAH 10T1.5 | 10x3x1,5 | 0.45 | 1.5 | 24.1 | 1.25 | 1.7 | 27.5 | 1435 |

| RE-2Y(St)HSWAH 12T1.5 | 12x3x1,5 | 0.45 | 1.5 | 24.9 | 1.25 | 1.7 | 28.4 | 1569 |

| RE-2Y(St)HSWAH 16T1.5 | 16x3x1,5 | 0.45 | 1.6 | 28.4 | 1.25 | 1.8 | 31.8 | 2162 |

| RE-2Y(St)HSWAH 20T1.5 | 20x3x1,5 | 0.45 | 1.7 | 31.6 | 1.25 | 1.9 | 34.9 | 2515 |

| RE-2Y(St)HSWAH 24T1.5 | 24x3x1,5 | 0.45 | 1.8 | 34.4 | 1.60 | 2.0 | 38.3 | 2879 |

Note : Other conductor sizes & core configurations are available upon request

Electrical PROPERTIES

| Conductor Area Size | mm 2 | 0.5 | 0.75 | 1.0 | 1.3 | 1.5 | |

| Insulation thickness (nominal) | mm | 0.35 | 0.38 | 0.4 | 0.45 | 0.45 | |

| Conductor resistance (20°C) | Ω/km | 36.7 | 25 | 18.5 | 14.2 | 12.3 | |

| Insulation resistance (20°C) | MΩ.km(Min.) | 5000 | |||||

| Mutual Capacitance (1 kHz) | pF/m(Max.) | ||||||

| ≤ 4 pairs | 90 | 90 | 90 | 102 | 102 | ||

| all other pairs | 75 | 75 | 75 | 85 | 85 | ||

| Capacitance unbalance(1 kHz) | pF/500 m (Max.) | 500 | |||||

| L / R (ratio) (max.) | μH/Ω | 25 | 25 | 25 | 40 | 40 | |

| Inductance | mH/km(Max.) | 1 | |||||

| Operating voltage Urms | V | 300 | |||||

| Test Voltage | Core to Core | V | 1500 | ||||

| Core to Screen | V | 1500 | |||||